- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Automatic packing for outbound delivery using Unif...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Automatic Packing in Outbound:

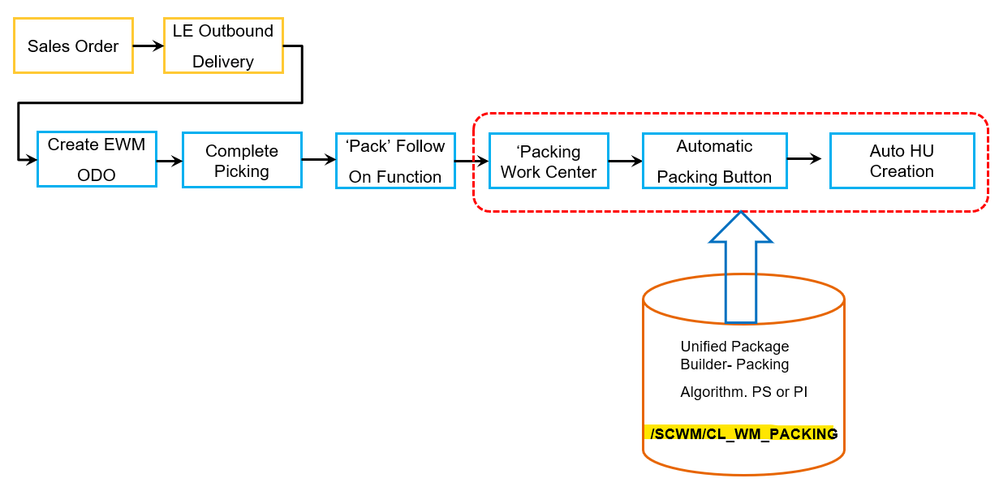

With S/4 HANA 2022 & higher version, it is now possible to conduct 'Automatic Packing' against Outbound delivery in EWM work center. The automatic packing functionality was available for Inbound process receiving against the Inbound delivery, same concept is extended to outbound process using more robust packaging algorithm through Unified package builder( UPB)

Long Packing Process-Earlier it was a tedious job to select every product/item manually and create HU’s to pack them in EWM work center,

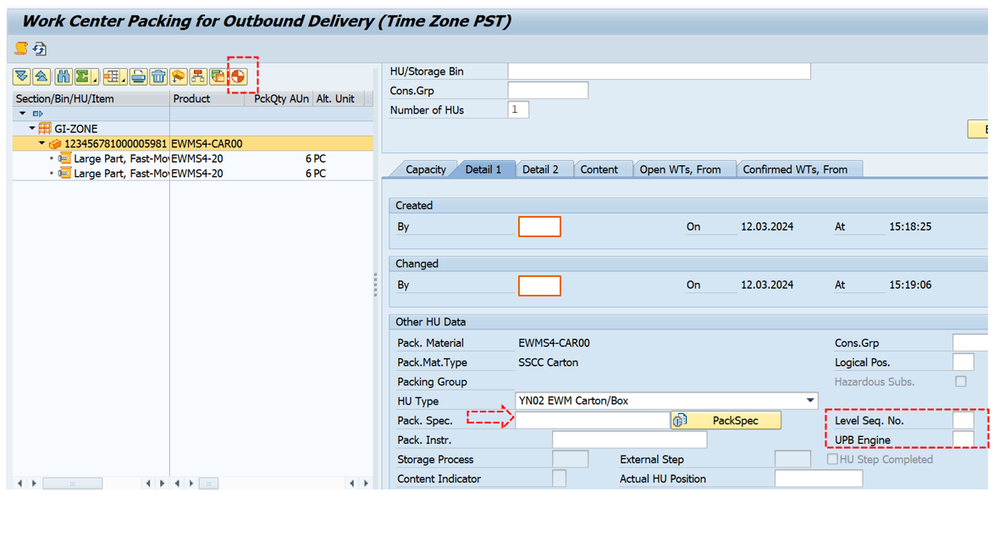

Current State -To make this process easier for the customers, auto pack functionality is introduced- where the customer can simply choose the product to be packed and click on “Auto pack” button which will identify the appropriate packaging materials of the products and create the handling units automatically.

Scope

• User can mark one or several stock items or a HU in the tree of the outbound work center

• The systems calls the Packing Instructions (PI) or Pack Specification (PS) via UPB for the directly marked stock and for the stock in a marked HU.

• If a PI or PS has been found the systems creates the Hus accordingly.

• If no PI or PS has been found the stock remains where it is.

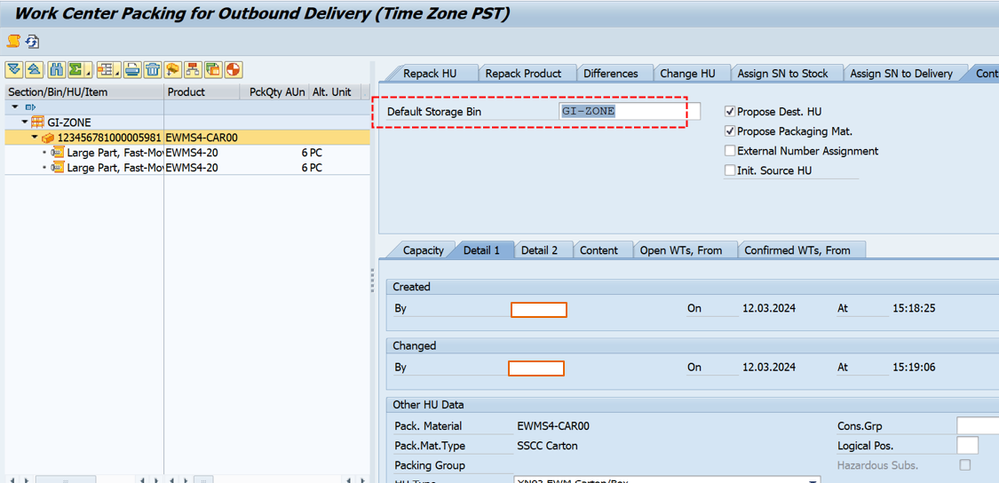

In below example, a delivery is already picked and confirmed via Pick HU( Non Homogeneous HU).

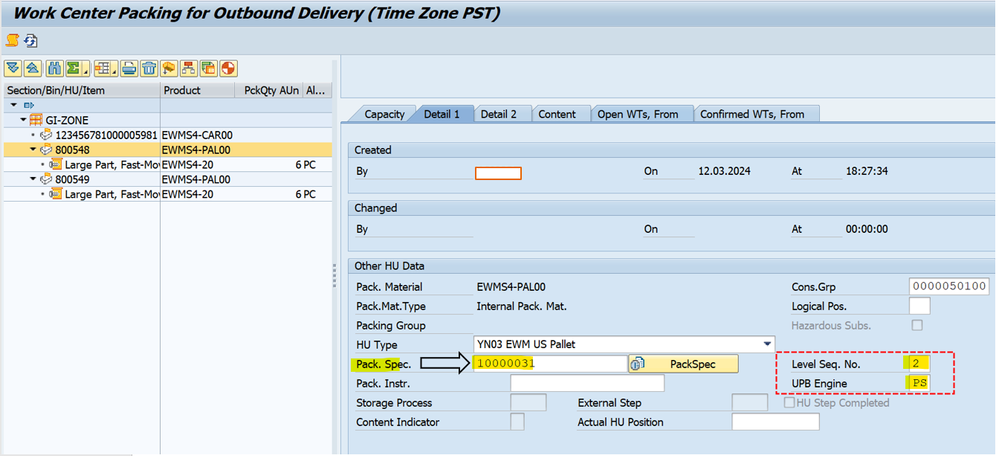

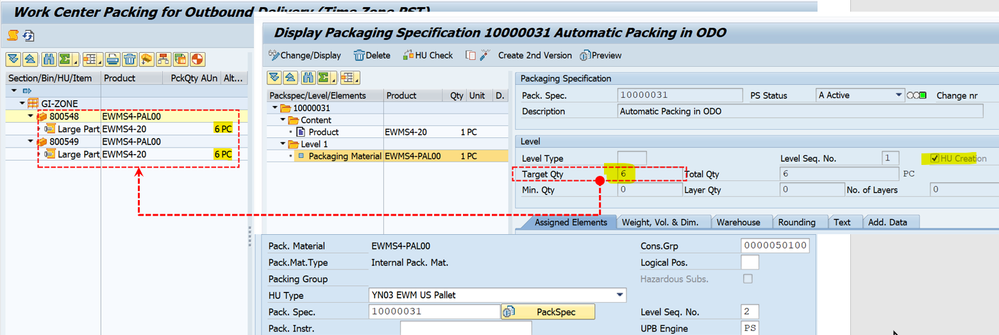

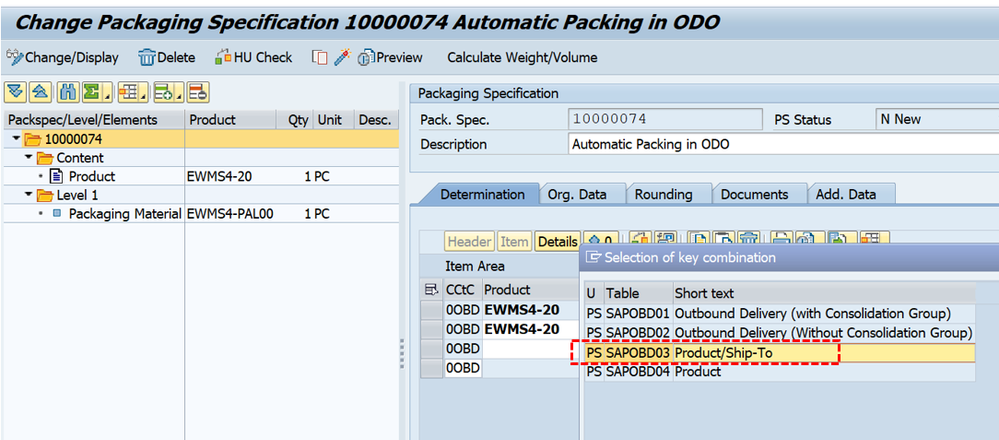

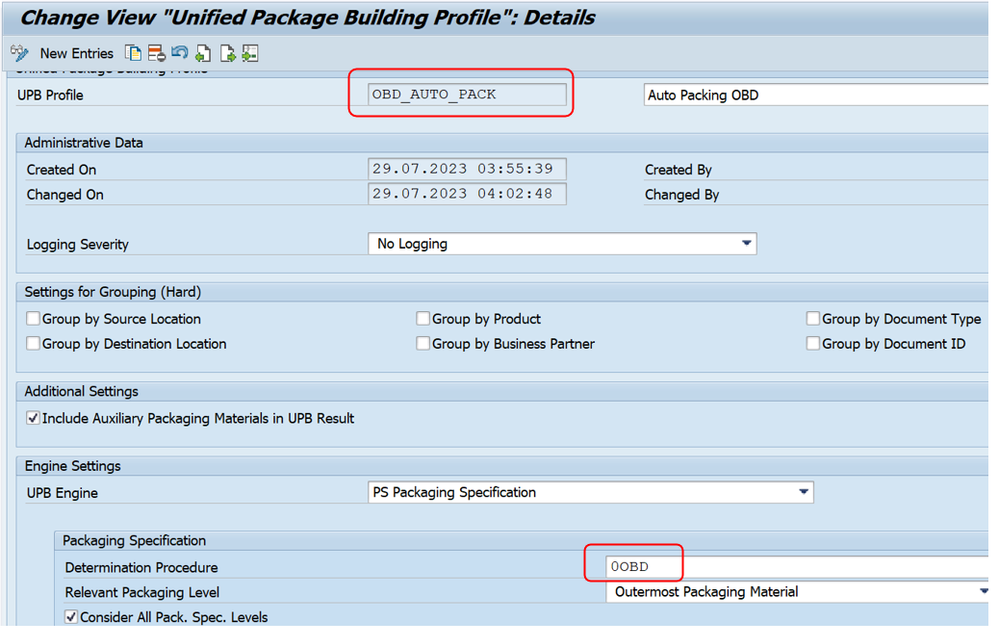

The system automatically packs using the packaging specification defined for condition 0OBD for product combination. UPB engine, sequence and packaging specification gets determined.

The product gets packed into 2 Shipping HUs as per the condition record 0OBD.

More robust packaging specification can be create using Product, Product Ship to, ODO with Consolidation Group & W/O consolidation group.

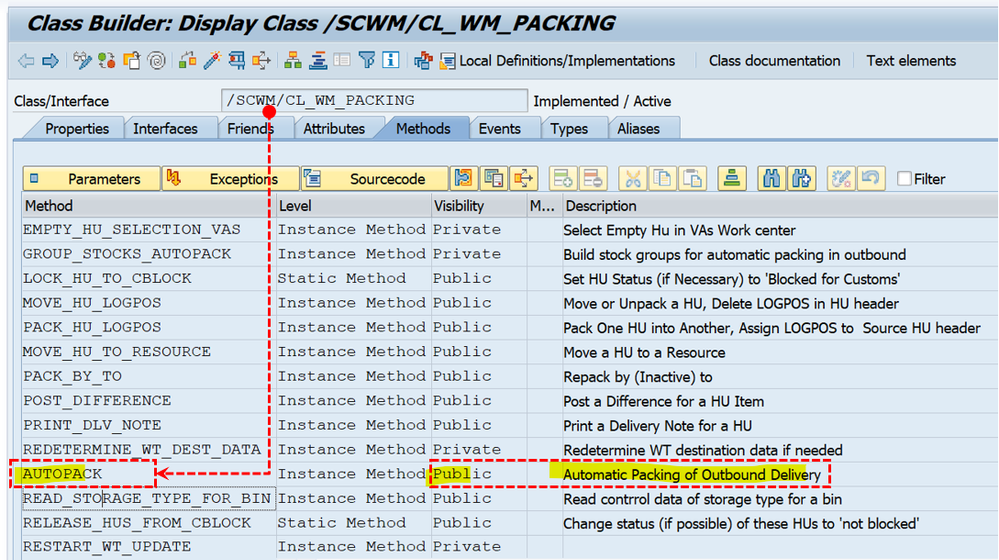

SAP has enabled a new method 'AUTOPACK' in Packing super class /SCWM/CL_WM_PACKING. This new method( Public) can be leveraged to built a Z report which could conduct automatic packing based on Picked ODO. You can use class /SCWM/CL_WM_PACKING method passing parameters IV_BIN (storage bin- Mandatory), ODO IV_PRDO, WC,IV_WORKSTATION. Please read all the import parameter in the class what are optional and mandatory

This Packing super class can also be used in Custom RF packing process for automatic Packing. In the code, we always create the Shipping HUs only for picked deliveries. There are also few exception related to serial numbers and Catch weight products.

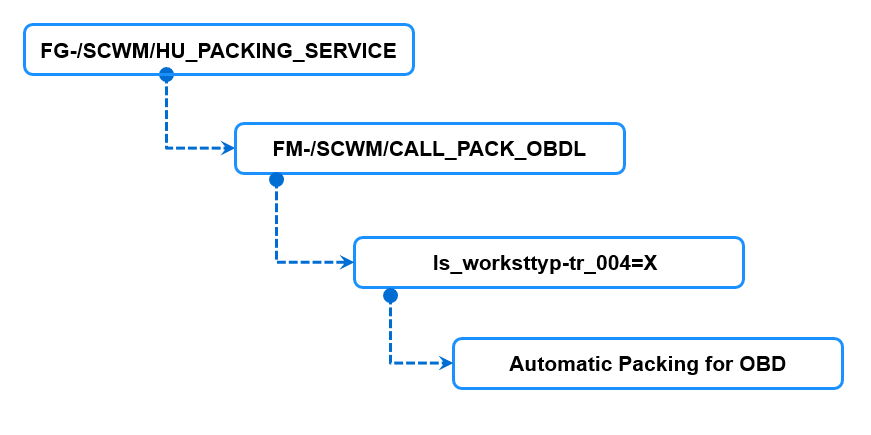

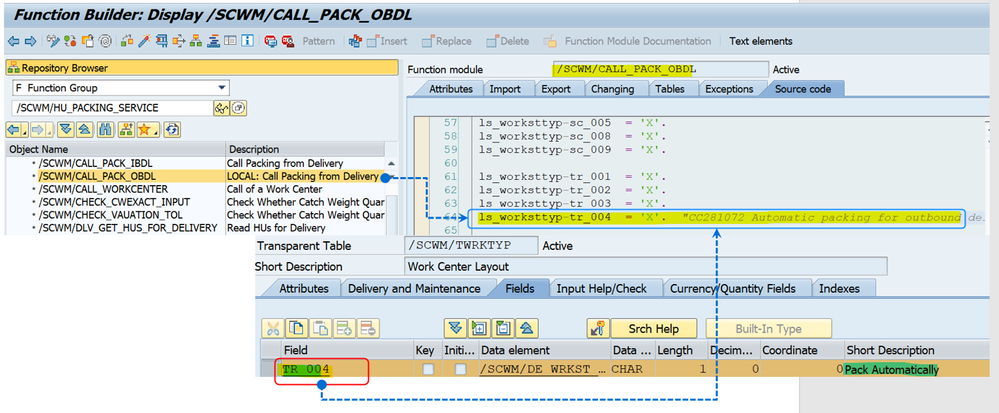

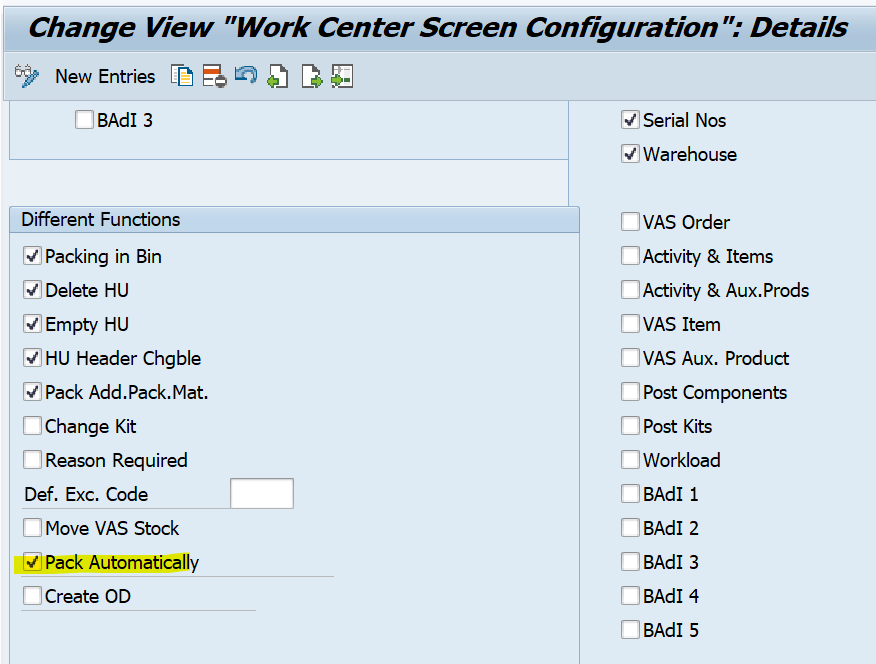

This functionality is enabled from S/4HANA 2022 & higher version. The note 3301323 -Automatic packing for outbound delivery introduces a check in FM /SCWM/CALL_PACK_OBDL to trigger automatic packing based on below condition. ls_workstty-tr_004 must be set to X, this is Packing work center layout which must facilitate 'Pack Automatically'

Configuration:

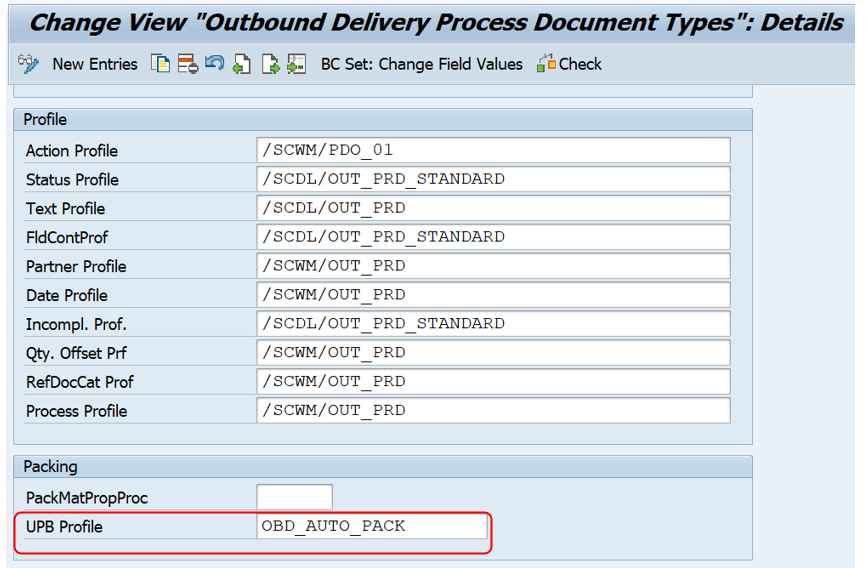

UPB setting: Doc type OUTB: Extended Warehouse Management-->Goods Issue Process-->Outbound Delivery-->Define Document Types for Outbound Delivery Process

UPB Setting:

Extended Warehouse Management-->Cross-Process Settings-->Handling Units-->Unified Package Building-->Define Unified Package Building Profile

Work center:

Extended Warehouse Management-->Master Data-->Work Center-->Specify Work Center Layout

Exceptions & condition for Automatic Packing

1) Only Picked delivery is relevant for Automatic Packing. /SCWM/PRDO will fail to trigger packing if it_stock and iv_prdo are initial .

2) Only picked stock with Serial Number( A & B) are supported. Serial number with C are not supported and kept out of scope from Automatic Packing.

3) Only picked stock´s without using catch weight are allowed for automatic packing

Thanks for reading. All tests have been performed in S/4 HANA 2022 Embedded EWM sandbox system.

- SAP Managed Tags:

- SAP Extended Warehouse Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

5 -

Expert Insights

12 -

Expert Insights

47 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

68 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

18

- Order Receipt/Delivery not possible , Credit customer blocked in Supply Chain Management Q&A

- Can’t Miss Asset and Service Management Sessions at SAP Sapphire 2024 in Orlando in Supply Chain Management Blogs by SAP

- Why Logistics Visibility is Best with SAP Business Network Global Track and Trace in Supply Chain Management Blogs by SAP

- SAP LMD/DSD - Last Mile Distribution in Supply Chain Management Blogs by SAP

- Forwarding agent as a generic use in Supply Chain Management Q&A

| User | Count |

|---|---|

| 9 | |

| 6 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |