- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Supply Protection in Supply Assignment(ARun)

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Introduction:

This blog explains how Supply Protection time buckets are considered in Supply Assignment(ARun). Supply Protection is used to protect minimum quantities maintained for specific characteristic combination (such as Customer, Distribution Channel, etc.) and represents future demand. Supply Assignment(ARun) is used to reserve supply for actual demand (Sales Orders, STOs, etc.). Hence it is essential to understand the behavior of Supply Protection in Supply Assignment to meet desired business needs.

Scenario:

Let us take an example where there are 3 channels (Wholesale, Ecommerce, Retail) competing for same inventory. Assume there is a need to protect inventory based on business priorities as shown below.

| Priority | Channel | Customer |

| 1 | Ecommerce | All Customers |

| 2 | Retail | All Customers |

| 2 | Wholesale | Customer A |

| 3 | Wholesale | All Others |

[Note - This example is a mixture of Horizontal and Vertical Protection]

Minimum Quantities to be protected:

| Priority | Channel | Customer | Feb | Mar | Apr |

| 1 | Ecommerce | All Customers | 50 | 50 | 50 |

| 2 | Retail | All Customers | 30 | 30 | 30 |

| 2 | Wholesale | Customer A | 20 | 20 | 20 |

Pre-Requisites:

- 'Advanced ATP' is activated for the checking group

- ‘With Supply Protection for Specific Document Types’ is enabled for the corresponding scope of check

- Material is enabled for Supply Assignment at the plant

Step 1:

Create a new Supply Protection Object in Fiori App Manage Supply Protection and Activate the object.

Supply Protection Setup

Step 2:

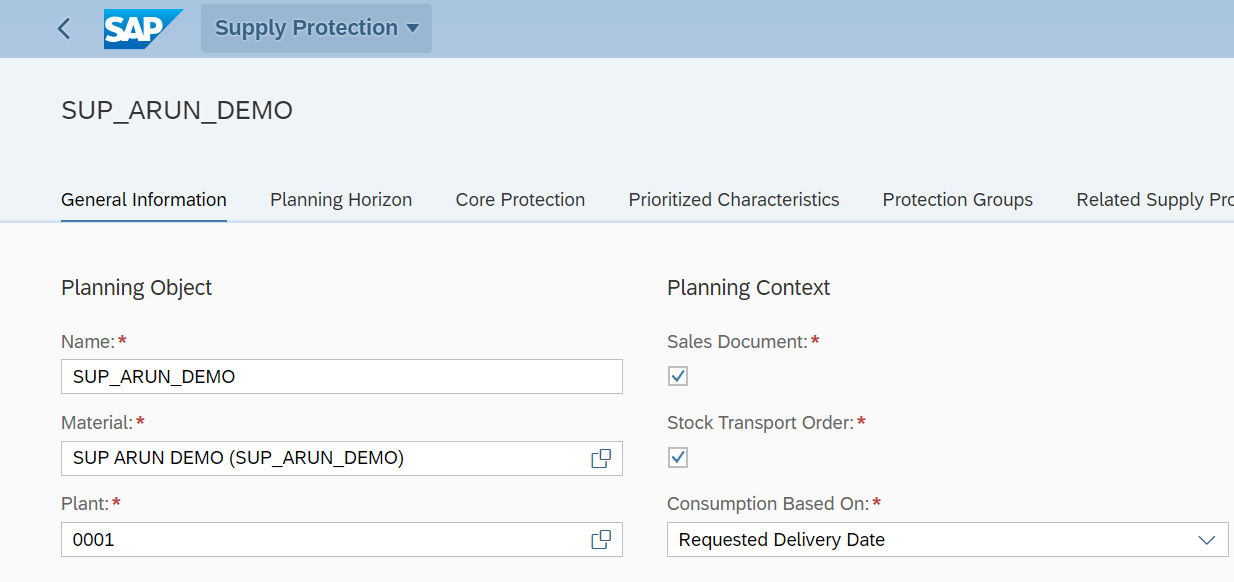

Maintain the general information and create the planning horizon for the supply protection (In this example, the SUP object is set up with monthly time buckets and consumption based on Requested Delivery Date of the actual demand).

Step 3:

Maintain Characteristics (In this example, the characteristics are Distribution Channel and Customer Number).

Step 4:

Maintain protection quantities for corresponding characteristic combination as shown below.

Supply Protection Setup

Step 5:

Supply is created in system as shown below:

| Supply | Delivery Date | Quantity |

| On Hand Stock | Today (Jan 15) | 120 |

| Purchase Order 1 | Feb 20 | 120 |

| Purchase Order 2 | Mar 25 | 120 |

Note: Purchase Orders are created in such a way that the future time buckets are covered.

Step 6:

Create a new Sales Order SO1 for Wholesale channel for Customer B with requested delivery date as Feb 7 and requested units as 100.

Once above details are entered, system will reserve the supply for the planned protection maintained in SUP object and the new sales order SO1 will get confirmations as shown below:

| SO1 Item | Requested Delivery Date | Requested Quantity | Confirmed Delivery Date | Confirmed Quantity |

| 10 | Feb 7 | 100 | Feb 7 | 20 |

| Feb 20 | 20 | |||

| Mar 25 | 20 |

Problem Statement: In Step 6, the confirmation results are as expected respecting supply protection. However it is also critical for business that SO1 does not take the on hand inventory during supply assignment process.

For example, assume that the supply assignment rule is configured with static supply sort rule as the priority says ( 1- On Hand Stock and 2 – Purchase Orders). When SO1 participates in supply assignment, below is the result.

| SO1 Item | Confirmed Delivery Date | Confirmed Quantity | Stock Source | Assigned Quantity |

| 10 | Feb 7 | 20 | C (On Hand) | 20 |

| Feb 20 | 20 | C (On Hand) | 20 | |

| Mar 25 | 20 | C (On Hand) | 20 |

Even though On hand stock is supposed to be reserved for high priority future demand for 100 units, SO1 has taken away the 40 units from the protected high priority time buckets. As a result, the next availability check will see only 60 on hand stock available and high priority protection buckets are in short of 40 units. So it is important to configure supply assignment rule accordingly.

In the subsequent steps, we can observe how this can be configured to work as expected respecting supply protection.

Step 7: Create a new Supply Assignment Rule in ‘Configure Supply Assignment Rule’ Fiori app and maintain a static supply sort rule and supply protection execution mode as ‘Consider Supply Protection(Upto Material Availability date)’.

Supply Assignment Rule Setup

With this configuration, system will consider the supply protection time buckets during supply assignment process as well. Below is the result of supply assignment process with above mentioned configuration.

| SO1 Item | Confirmed Delivery Date | Confirmed Quantity | Stock Source | Assigned Quantity |

| 10 | Feb 7 | 20 | C (On Hand) | 20 |

| Feb 20 | 20 | Purchase Order 1 | 20 | |

| Mar 25 | 20 | Purchase Order 2 | 20 |

Appendix:

SAP Help:

SAP Community Blogs:

- SAP Managed Tags:

- SAP Fashion Management,

- SAP S/4HANA,

- SAP S/4HANA for advanced ATP

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

29 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

28 -

Expert Insights

114 -

Expert Insights

186 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

414 -

Life at SAP

2 -

Product Updates

4,679 -

Product Updates

267 -

Roadmap and Strategy

1 -

Technology Updates

1,499 -

Technology Updates

98

- SAP S/4HANA - Extracting User Email Addresses from Standard Tables in Enterprise Resource Planning Blogs by SAP

- How to assign source of supply for all line items in sales order? in Enterprise Resource Planning Q&A

- Quantity Distribution in Enterprise Resource Planning Blogs by SAP

- Incorrect PRs for RM where FG made at external vendor and we order RM for vendor in Enterprise Resource Planning Q&A

- Adding Custom Fields to Migration Objects in SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 7 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |