- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- How to create Production Versions for our journey ...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

2020 Apr 14

6:04 PM

11,398

- SAP Managed Tags:

- SAP ERP,

- SAP S/4HANA,

- MAN Production Planning (PP)

As we all know Production versions are mandatory in S/4HANA. MRP, planned order creation, and production order creation only finds a BOM and a routing alternative if a production version is maintained for the BOM and routing alternative.

The benefits of having production versions are listed below:

As Production Versions are mandatory there are also a few functionality changes in S/4HANA that we need to be aware off:

Our focus from a Production Planning perspective before moving to S/4HANA is to create any missing production versions. Please note this is not a mandatory activity but more a recommendation as creating PV in our ERP system and having them ready, before we move our system to S/4HANA not only will it save us a big amount of time it will also aid business users to get familiar with this change.

In addition as we already have our MRP areas created that would mean we would have to do very few post conversion activities from a Production Planning perspective as we will just need to run some reports (more on that in the follow-up blog).

Below is a guide on how to perform the activities of creating Production Versions in a mass and organized way:

Note 2463759 brings the report in our ERP system if you have at least SAP_APPL 617 or 618

https://launchpad.support.sap.com/#/notes/2463759

Also note that there are additional notes that need to be implemented to get the full scope and full functionality of the report, but more details in this regard are below.

The report is divided into 4 parts that limit the scope on how the reports runs:

Material: Here you can filter on how you run the report; We can limit the scope to materials, plants or material types;

BOM: Status/Usage

Routing: We can select if we want to run the report on a limited scope of just selection type”N”

Migration Criteria: The recommended setting is “Based on Production Orders”; That way we limit our report running time as it only focuses on the materials which have been produced;

In case you want to run the report system wide, depending on the number of materials it can take anywhere from minutes to several hours

There are a multitude of options and variables to chose and each customer should choose the ones that make the most sense from a business and time perspective.

Tips and tricks:

The latest notes are:

https://launchpad.support.sap.com/#/notes/2849261

https://launchpad.support.sap.com/#/notes/2830739

https://launchpad.support.sap.com/#/notes/2803486

The follow-up blog will detail what post-conversion activities are required in S/4HANA.

Thank you and stay tuned.

The benefits of having production versions are listed below:

- Production versions allow to define which BOM alternative goes together with which routing alternative

- Mandatory production versions make MRP sourcing simpler. There is only one option to determine BOM and routing alternatives for a manufactured material

- There is no need to control MRP sourcing with additional control indicators like the selection method MARC-ALTSL in the material master

- Production versions are mandatory in PP/DS. PP/DS is an integral part of S/4HANA. Mandatory production versions make sourcing in MRP and PP/DS more similar

- Sourcing for manufactured and for purchased parts is more similar. In S/4HANA production versions are the source of supply for manufactured materials. Purchasing info records, contracts, and delivery schedules are the possible sources of supply for purchased parts. Every possible source of supply has temporal validity, lotsize interval, and a status, which blocks using the source of supply in MRP, but not in manual sourcing.

As Production Versions are mandatory there are also a few functionality changes in S/4HANA that we need to be aware off:

Just to name a few:

- The Selection Method field in MRP4 view of material master is now deprecated.

- Not relevant to BOM determination anymore: Lot Size entries in BOM Header and Items do not exist in S/4HANA anymore

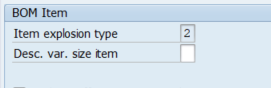

- The customizing that determines the items valid for BOM explosion now has the default value ‘2

Our focus from a Production Planning perspective before moving to S/4HANA is to create any missing production versions. Please note this is not a mandatory activity but more a recommendation as creating PV in our ERP system and having them ready, before we move our system to S/4HANA not only will it save us a big amount of time it will also aid business users to get familiar with this change.

In addition as we already have our MRP areas created that would mean we would have to do very few post conversion activities from a Production Planning perspective as we will just need to run some reports (more on that in the follow-up blog).

Below is a guide on how to perform the activities of creating Production Versions in a mass and organized way:

- We need to create Production Versions for all the materials in use by using report CS_BOM_PRODVER_MIGRATION02

Note 2463759 brings the report in our ERP system if you have at least SAP_APPL 617 or 618

https://launchpad.support.sap.com/#/notes/2463759

Also note that there are additional notes that need to be implemented to get the full scope and full functionality of the report, but more details in this regard are below.

- Run report CS_BOM_PRODVER_MIGRATION02 via transaction code SE38.

The report is divided into 4 parts that limit the scope on how the reports runs:

Material: Here you can filter on how you run the report; We can limit the scope to materials, plants or material types;

BOM: Status/Usage

Routing: We can select if we want to run the report on a limited scope of just selection type”N”

Migration Criteria: The recommended setting is “Based on Production Orders”; That way we limit our report running time as it only focuses on the materials which have been produced;

In case you want to run the report system wide, depending on the number of materials it can take anywhere from minutes to several hours

There are a multitude of options and variables to chose and each customer should choose the ones that make the most sense from a business and time perspective.

- Running the report

- Running it in Simulation Mode: Is a good starting point as the system will show what materials need a Production Version

- Running it in Active Mode: Will show you the materials which need a production version and will let you Approve individually or by Selecting all of them and Approve All(time consuming as it runs in foreground)

- Running it in Active Mode with Background Mode means that system will search for all materials, propose and automatically approve the creation of Production Versions---If this is used please Execute in Background so you can monitor the time it takes---

Tips and tricks:

- Involve business users in the process

- Test out the report on a couple of materials first and observe how the report behaves and what Production Version it is suggesting

- Record the time the report took for a small batch of materials and extrapolate the time as this action will need to be done in all the systems in your landscape (sandbox, dev,quality and production) as a Pre-Conversion step in case of a Brownfield Conversion; Running it in background will score different times depending on system resources and master data.

- Please search for all relevant notes that add additional functionalities to the report:

The latest notes are:

https://launchpad.support.sap.com/#/notes/2849261

https://launchpad.support.sap.com/#/notes/2830739

https://launchpad.support.sap.com/#/notes/2803486

The follow-up blog will detail what post-conversion activities are required in S/4HANA.

Thank you and stay tuned.

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

API and Integration

1 -

Artificial Intelligence (AI)

1 -

Business Trends

361 -

Business Trends

79 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

454 -

Event Information

65 -

Expert Insights

109 -

Expert Insights

452 -

General

2 -

Governance and Organization

1 -

Great Britain

1 -

Introduction

1 -

Life at SAP

408 -

Life at SAP

8 -

Product Updates

4,606 -

Product Updates

578 -

Roadmap and Strategy

1 -

Technology Updates

1,489 -

Technology Updates

232

Related Content

- Connecting SAP BTP and On-Premise SAP Business One using the SAP Cloud Connector in Enterprise Resource Planning Blogs by SAP

- Streamlining Capacity Evaluation with the SAP Fiori App in Enterprise Resource Planning Blogs by Members

- Planning Table for 2 or more workcenters (repetitive manufacturing in Enterprise Resource Planning Q&A

- Artificial Intelligence and other Innovations in SAP S/4HANA Cloud Private Edition 2023 FPS02 in Enterprise Resource Planning Blogs by SAP

- 12 Things that SAP implementation methodology SAP Activate tells you to do in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 7 | |

| 5 | |

| 5 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |