- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Source inspection with multiple inspection results

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Master data

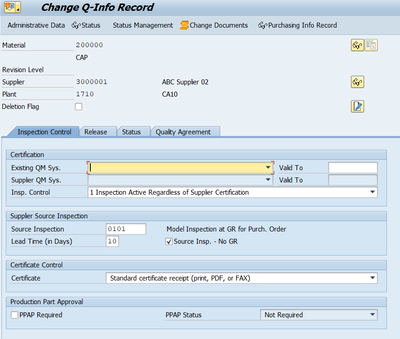

Quality info record

The Q-Info Record is utilized to initiate a source inspection lot for a specific material/vendor and plant combination.

To create quality info record go to QI01 with selection of material and supplier

- Active “Source inspection” in inspection control tab

- Set inspection control “Inspection active regardless of supplier certification”, If you not select this inspection lot will not be create at GR.

- If you prefer to generate an inspection lot upon Goods Receipt (GR) for a source inspection lot, do not select the checkbox labelled "Source Insp. No GR".

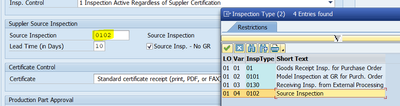

- Set inspection type 0102 for source inspection

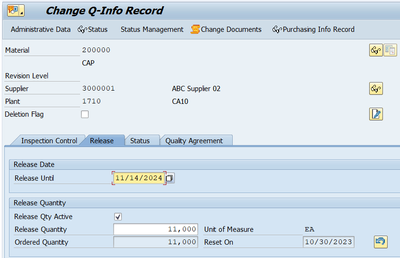

- Set validity of quality info record in release until which is in release tab.

- Then save.

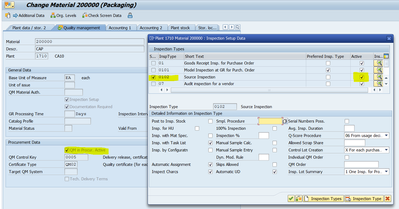

Material master

- QM active in material master go to MM02

- Open material master

- Set active “QM in Procurement Is Active”

- Active inspection type 0102 Source Inspection.

Create inspection plan

(For record one time result inspection plan will be same as you created before for multi time result recording on one source inspection lot follow below procedure)

- To create inspection, go to QP01

- Set usage 52 GR Source Inspection

- Overall status 4 Released (General)

- Set Inspection point according to requirement (I am selecting Quantity wise).

- Attaché MICs according to your testing plan

- Set sampling procedure which have “Other inspection point”

- Create sampling procedure from QDV1 if not created

- Set others in inspection point.

Transaction

- Create purchase order

- Create purchase order go to ME21N with selection of same vender which you create Quality info record,

- To trigger the lot manually you need to have some open purchase orders for the material/plant/vendor.

- Go to transaction QI07 and give the material code, vendor, plant and opening period.

- Add material code and supplier

- Then execute

- Select scheduled order line go to select create inspection lot then press save.

For run on background job to create source inspection lot automatically try QA51

- Go to inspection lot.

- Select inspection lot.

- Enter Qty and date.

- Record inspection results against inspection point

- At the time of usage decision, you can check multiple results Qty and date wise

Do result recording for each inspection point.

when product is finally accepted give usage decision.

after usage decision you can not record results.

- SAP Managed Tags:

- SAP Data Quality Management,

- SAP Quality Issue Management,

- SAP Quality Issue Resolution

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Advance Shipping and Receiving

1 -

Adverse media monitoring

1 -

AI in Logistics

1 -

Alerts

1 -

Ariba

1 -

ASR

1 -

Ausnahmehandling

1 -

Automation

1 -

bank statements

1 -

BI

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business Network for Logistics

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Change History

1 -

Charge Calculation

3 -

Cloud Extensibility

1 -

compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Analysis

1 -

Data Enrichment

1 -

decentralized ewm

2 -

Delivery

1 -

Delivery & Transportation

1 -

Demand

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

7 -

EWM - Delivery Processing

4 -

EWM - Goods Movement

5 -

EWM - Interleaving with RF

1 -

EWM Monitor

2 -

EWM Outbound

1 -

EWM Outbound configuration

2 -

EWM-RF

1 -

EWM-TM-Integration

2 -

Extended Warehouse Management (EWM)

5 -

Extended Warehouse Management(EWM)

7 -

FINANCE

1 -

Forecast Consumption

1 -

forecasting

1 -

Freight Agreement

1 -

Freight Order

1 -

Freight Settlement

2 -

FSM

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

illuminator services

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics

1 -

Logistics Optimization

2 -

Map Integration

1 -

Material Management

1 -

Material Master changes

1 -

Materials Management

1 -

MDO queries in SAP MII

1 -

MDOs

1 -

MFS

1 -

New Feature

1 -

outbound delivery

1 -

Outbound queue

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

Physical Inventory

1 -

PHYSICAL INVENTORY EWM

1 -

PowerBI

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

SAC

1 -

Sales and Distribution

1 -

Sales and Operations

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP EWM

2 -

SAP Extended Warehouse Management

2 -

SAP Extended Warehouse Management (SAP EWM)

1 -

SAP Fiori

1 -

SAP FSM

1 -

SAP Hana Spatial Services

1 -

SAP IBP

2 -

SAP IBP IO

1 -

SAP MDO

1 -

SAP MII

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

2 -

SAP Transportation Management

6 -

SAP UI5

1 -

SAP Variant configuration (LO-VC)

1 -

SAPEWM

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

2 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TM-GTS Integration

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

3 -

Trends

1 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

- Enhance your maintenance and field technicians’ efficiency and productivity with SAP Dynamic Forms in Supply Chain Management Blogs by SAP

- Copy results from lot with Insp. Type 03 to the lot with Insp. type 04. in Supply Chain Management Q&A

- aquatherm Improves Operations with SAP Digital Manufacturing in Supply Chain Management Blogs by SAP

- How to create multiple inspection lots by using same process order in Supply Chain Management Q&A

- Quality inspection before Ship notice in Supply Chain Management Q&A

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |