- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Introduction to Capacity Requirement planning in S...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-22-2021

4:39 PM

You are running a manufacturing company and following an aim to deliver customer’s orders on the dates promised. You, therefore, want to ensure to plan sufficient but not excessive capacity available at the work center to cover capacity requirements required for the orders. Managing production schedule with effective utilization of capacity is a tightrope walk for a capacity planner when dealing with scheduling of multiple orders involving bottleneck operations to be carried out at the work center.

The execution of orders with the planning step of dispatching capacity requirements to a work center in question requires skillful assessment with consideration to the comprehensive factors so as not to deviate from the original schedule of the dates promised for the queue of orders which might get affected due to the ever-changing situations at the manufacturing plant due to various reasons.

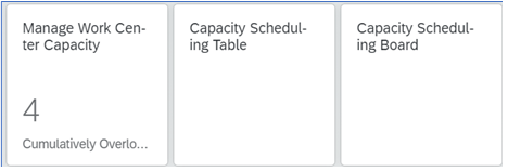

I am writing this blog post to provide an overview on the interesting topic of Capacity planning and will walk you through the SAP Fiori Apps available to handle Capacity requirement planning, i.e. ‘Manage work center capacity’, ‘Capacity scheduling table’ and ‘Capacity scheduling board’. These Fiori Apps provide better user experience with user friendly UI to handle functions of capacity evaluation, Scheduling, and capacity leveling. With the effective trio of the apps available to the manufacturing users running production planning for SAP S/4HANA on Premise as well as SAP S/4HANA Cloud.

Let’s quickly touch upon the basic terms used in capacity planning such as required master data, available capacity, Scheduling, Capacity requirement, Capacity evaluation, Capacity leveling and Reduction of capacity.

Master data such as material master, work center or resource (in PP-PI) Routing or master recipe, Calendar, Shift definition, Sequence and type of capacity form the elements of capacity management which play an important role to carry out the functions available capacity, Scheduling, Capacity requirement, Capacity evaluation, Capacity levelling and Reduction of capacity. The available capacity is a measure of the work that capacity can perform per workday.

Capacity requirement is a measure of the work required by the individual orders at a capacity at a certain point in time.

In the capacity evaluations, these requirements can be compared with available capacities.

The main function of capacity leveling is to dispatch operations. Operations are dispatched for the purpose to fix them at a point in time when sufficient capacity is available. In addition to this, capacity shortfalls and overloads can be leveled with capacity leveling. You can use alternative suitable resource/s for processing, or you can use sort the operation using graphical capacity leveling board to sort to achieve optimal loading.

In contrast to the lead time scheduling which uses unlimited available capacity at the work center and does not consider available load on the work center, Finite scheduling schedules the operations with taking into consideration the current load on the work center.

Capacity reduction takes place when operations are confirmed, or order quantities are reduced or cancelled.

Now let’s understand the role of the three Fiori Apps which provides a better user experience to the production scheduler to work effectively with capacity planning.

Manage work center capacity

With Manage work center capacity app, the planner can visualize status of capacity at the work center/s, with bucket of days / weeks with load in percentage / hours for orders such as Planned order, Production order / Process orders.

Overview: The overview section of the app provides detailed information for a work center on utilization of the capacity to the planner with graphical bar chart with identification of load with option to select the list with cumulative overload, Overload, Underload and All with the option to choose the unit in percentage or Hours colors identifying load on the work center during the bucket of time. Green color represents optimum loading of capacity, for example, up to 80%), yellow color can be set to represent 80-100%, while red color shows overload (Above 100 %) User can select the evaluation with option to select overload cumulative overload situation across the selected evaluation horizons based on the type of buckets, such as days or weeks.

Operations: This section provides details of the operations as part of orders planned at the same work center with the status of planning such as dispatched or not dispatched and utilization percentage of capacity for that operation.

Shifts: This section of the app details the available capacity during the evaluation period. The information relevant to shift definition, Shift timings, with shift utilization percentage along with number of capacity and shift capacity in Hours. A planner can also add shift or shift interval for managing capacity requirements.

Capacity scheduling table

The Fiori app ‘Capacity scheduling table’, provides series of features to work with the planned and Production order / Process orders as per the option to set industry type. Strategy can be set for planning mode selection between bucket / sequence, Scheduling control with option to select from finite and infinite scheduling and direction such as Forward / Backward. This Fiori App provides planner an option to select the source of supply (production version) and the work centers to dispatch the orders on the dates that you choose. Set number of days possible to schedule orders in the past and future, Execution of mass Dispatching or de-allocation of order operations, Filter and resolve late or overdue orders, realign scheduled orders to past or future date and time, Option to navigate to the Advanced Variant configuration screen to view configuration in Production order, reschedule or de-allocate a scheduled operation to a different date, firm or un-firm allocated planned orders, Show the source of supply based on available sources such as Production versions, Select the option to use pacemaker work centers for dispatching your order to it. Pacemaker work center can be set in production version.

With a pacemaker work center the entire order for the rest of the un-dispatched operations follow Midpoint scheduling method to align with the pacemaker operation involving pacemaker work center is dispatched. Further functionalities possible with this app includes guide with time slot available to dispatch the order, Change the sequence of order in the sequence table using the drag-and-drop feature and other display feature and additional support options with technical features for email and SAP jam Integration.

Capacity scheduling board

With Capacity scheduling board Production scheduler can view work centers with schedules on a chart for a selected time based on filter criteria such as product number, scheduling status, plant, MRP area, etc. Strategy can be set to select the Scheduling Control and Direction for your scheduling, whereas here the planning mode is always of type ‘Sequence’.

You can select operation in a [pacemaker work center on the chart and can manage operation with work on the schedule of the operation by changing the start or end of the operation based on the direction set for reschedule the operation. You can select available free slot on the chart and choose to dispatch this operation to that slot. Also you can de-allocate the dispatched operation and view operation info.

Conclusion

This blog post should help you to understand in detail Capacity Requirement planning fundamentals and the to familiarise you with the FIORI apps available in S/4HANA

Thanks for reading this blog post, hopefully this blog post is informative.

Reference: FIORI app Library

FIORI APPs

1. Manage work center capacity

2. Capacity scheduling table

3. Capacity scheduling board

The execution of orders with the planning step of dispatching capacity requirements to a work center in question requires skillful assessment with consideration to the comprehensive factors so as not to deviate from the original schedule of the dates promised for the queue of orders which might get affected due to the ever-changing situations at the manufacturing plant due to various reasons.

I am writing this blog post to provide an overview on the interesting topic of Capacity planning and will walk you through the SAP Fiori Apps available to handle Capacity requirement planning, i.e. ‘Manage work center capacity’, ‘Capacity scheduling table’ and ‘Capacity scheduling board’. These Fiori Apps provide better user experience with user friendly UI to handle functions of capacity evaluation, Scheduling, and capacity leveling. With the effective trio of the apps available to the manufacturing users running production planning for SAP S/4HANA on Premise as well as SAP S/4HANA Cloud.

Let’s quickly touch upon the basic terms used in capacity planning such as required master data, available capacity, Scheduling, Capacity requirement, Capacity evaluation, Capacity leveling and Reduction of capacity.

Master data such as material master, work center or resource (in PP-PI) Routing or master recipe, Calendar, Shift definition, Sequence and type of capacity form the elements of capacity management which play an important role to carry out the functions available capacity, Scheduling, Capacity requirement, Capacity evaluation, Capacity levelling and Reduction of capacity. The available capacity is a measure of the work that capacity can perform per workday.

Capacity requirement is a measure of the work required by the individual orders at a capacity at a certain point in time.

In the capacity evaluations, these requirements can be compared with available capacities.

The main function of capacity leveling is to dispatch operations. Operations are dispatched for the purpose to fix them at a point in time when sufficient capacity is available. In addition to this, capacity shortfalls and overloads can be leveled with capacity leveling. You can use alternative suitable resource/s for processing, or you can use sort the operation using graphical capacity leveling board to sort to achieve optimal loading.

In contrast to the lead time scheduling which uses unlimited available capacity at the work center and does not consider available load on the work center, Finite scheduling schedules the operations with taking into consideration the current load on the work center.

Capacity reduction takes place when operations are confirmed, or order quantities are reduced or cancelled.

Now let’s understand the role of the three Fiori Apps which provides a better user experience to the production scheduler to work effectively with capacity planning.

Manage work center capacity

With Manage work center capacity app, the planner can visualize status of capacity at the work center/s, with bucket of days / weeks with load in percentage / hours for orders such as Planned order, Production order / Process orders.

Overview: The overview section of the app provides detailed information for a work center on utilization of the capacity to the planner with graphical bar chart with identification of load with option to select the list with cumulative overload, Overload, Underload and All with the option to choose the unit in percentage or Hours colors identifying load on the work center during the bucket of time. Green color represents optimum loading of capacity, for example, up to 80%), yellow color can be set to represent 80-100%, while red color shows overload (Above 100 %) User can select the evaluation with option to select overload cumulative overload situation across the selected evaluation horizons based on the type of buckets, such as days or weeks.

Operations: This section provides details of the operations as part of orders planned at the same work center with the status of planning such as dispatched or not dispatched and utilization percentage of capacity for that operation.

Shifts: This section of the app details the available capacity during the evaluation period. The information relevant to shift definition, Shift timings, with shift utilization percentage along with number of capacity and shift capacity in Hours. A planner can also add shift or shift interval for managing capacity requirements.

Capacity scheduling table

The Fiori app ‘Capacity scheduling table’, provides series of features to work with the planned and Production order / Process orders as per the option to set industry type. Strategy can be set for planning mode selection between bucket / sequence, Scheduling control with option to select from finite and infinite scheduling and direction such as Forward / Backward. This Fiori App provides planner an option to select the source of supply (production version) and the work centers to dispatch the orders on the dates that you choose. Set number of days possible to schedule orders in the past and future, Execution of mass Dispatching or de-allocation of order operations, Filter and resolve late or overdue orders, realign scheduled orders to past or future date and time, Option to navigate to the Advanced Variant configuration screen to view configuration in Production order, reschedule or de-allocate a scheduled operation to a different date, firm or un-firm allocated planned orders, Show the source of supply based on available sources such as Production versions, Select the option to use pacemaker work centers for dispatching your order to it. Pacemaker work center can be set in production version.

With a pacemaker work center the entire order for the rest of the un-dispatched operations follow Midpoint scheduling method to align with the pacemaker operation involving pacemaker work center is dispatched. Further functionalities possible with this app includes guide with time slot available to dispatch the order, Change the sequence of order in the sequence table using the drag-and-drop feature and other display feature and additional support options with technical features for email and SAP jam Integration.

Capacity scheduling board

With Capacity scheduling board Production scheduler can view work centers with schedules on a chart for a selected time based on filter criteria such as product number, scheduling status, plant, MRP area, etc. Strategy can be set to select the Scheduling Control and Direction for your scheduling, whereas here the planning mode is always of type ‘Sequence’.

You can select operation in a [pacemaker work center on the chart and can manage operation with work on the schedule of the operation by changing the start or end of the operation based on the direction set for reschedule the operation. You can select available free slot on the chart and choose to dispatch this operation to that slot. Also you can de-allocate the dispatched operation and view operation info.

Conclusion

This blog post should help you to understand in detail Capacity Requirement planning fundamentals and the to familiarise you with the FIORI apps available in S/4HANA

Thanks for reading this blog post, hopefully this blog post is informative.

Reference: FIORI app Library

FIORI APPs

1. Manage work center capacity

2. Capacity scheduling table

3. Capacity scheduling board

- SAP Managed Tags:

- SAP Fiori,

- MAN (Manufacturing),

- SAP S/4HANA Cloud Public Edition

Labels:

19 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

41 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

37 -

Expert Insights

114 -

Expert Insights

224 -

General

2 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

413 -

Life at SAP

3 -

Product Updates

4,672 -

Product Updates

309 -

Roadmap and Strategy

1 -

Technology Updates

1,495 -

Technology Updates

122

Related Content

- Discover the World of Poultry: From Farm to Fork with E2E Supply chain in SAP S4HANA Private Cloud in Enterprise Resource Planning Blogs by Members

- SAP S/4HANA Cloud Public Edition - Finance-Cost Accounting - Frequently Asked Questions in Enterprise Resource Planning Blogs by SAP

- Blog Series: S/4 HANA Cloud Public Edition – 01 Introduction & Supplier Delivery Prediction using AI in Enterprise Resource Planning Blogs by Members

- Troubleshooting for Business Partner Replication issues in Enterprise Resource Planning Blogs by SAP

- Defining Custom Partner Functions for BDRs and Invoices of Service Contracts in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 12 | |

| 9 | |

| 8 | |

| 8 | |

| 6 | |

| 6 | |

| 6 | |

| 5 | |

| 5 | |

| 5 |