- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Intelligent ERP Update: Manufacturing and Supply C...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Here is the table of contents:

1. Inventory Management

1.1. Prediction of Slow or Non-Moving Materials

1.2. Cycle Counting in Physical Inventory

2. Production Planning

2.1. Predictive Material and Resource Planning (pMRP)

2.2. Material Requirements Planning - Purchase Requisition Handover

2.3. Default MRP Areas Assignment & Profile

3. Integrated Product Development for Discrete Industries

3.1. Order Bill-of-Material (BOM) for Make-to-Order business

4. Process Management

4.1. Third-Party Shop Floor Execution - Process Industry

5. Warehouse Management

5.1. KANBAN process improvements

5.1.1. Reverse KANBAN Status from FULL to EMPTY in KANBAN Correction

5.1.2. Default Exception Code for Setting KANBAN FULL with Difference Quantity

5.1.3. Material Document and GM Document displayed in KANBAN Information

5.2. Partial Save Enablement for Physical Inventory

5.3. Replenishment in Warehousing

6. Transportation Management

6.1. Carrier settlement processing

6.2. Freight Orders with Calculation Errors

My video guides you through four selected innovations from the above table of contents:

- Prediction of Slow or Non-Moving Materials in Inventory Management

- Order Bill of Material for Make-to-Order business

- Third-Party Shop Floor Execution - Process Industry

- Predictive Material and Resource Planning (pMRP)

1. Inventory Management

1.1. Prediction of Slow or Non-Moving Materials

Figure 1 illustrates the general progress of a material in the product life cycle. In the initial phase the consumption and stock quantity is very high but both graphs almost run in parallel which continues to happen in in the fast mover and medium mover phase of the material. But in the transition from the medium mover to slow mover, consumption and stock value is drifting apart – consumption is dropping more less drastically which results in a stock surplus. With the slow moving indicator customers can now categorize their materials according to their individual criteria. The Slow Moving Indicator (SMI) represents a key figure which is a consumption to stock ratio normalized by a time period. If the customer uses the prediction / predictive model, it is now possible to anticipate the transition phase to a slow mover in a better way. The prediction in combination with the active Bill of Material (BOM) usage of a material can give valuable hints on the position of a material in the product life cycle so that customers can take early and informed actions.

Fig. 1: Product life cycle: Transition from fast to slow mover

The analytical list page Slow or Non-Moving Materials enables inventory managers to determine slow-moving materials via the Slow-Moving Indicator which is calculated based on the consumption to stock ratio. Now, with the 1911 release, we have introduced a detailed page that provides additional insights on the future development of a material in the product life cycle, using predictive analytics. The new detailed page provides a lot of information from different perspectives on various charts:

- Slow-Moving Indicator over Time

- Stock Situation and BOM Usage over Time

- Active BOM Usage

- Slow-Moving Indicator by Plants

The Active BOM Usage chart provides an overview of all valid Bills of Material for a specific reference date, which are using the selected material as a component.

The new Slow or Non-Moving Material Details by Plant/Material page offers several navigation links to other apps like Material Documents Overview or Transfer Stock - Cross Plant which allows an inventory manager directly to create a stock transport order. If you assign additionally the BOM engineer role to your user profile, you can use the BOM navigation links from the Active BOM Usage chart.

It is even possible to receive the forecast information for the Predicted Slow-Moving Indicator using the Predictive Analytics Model. For doing this activate the Predictive Scenarios for Consumption and Stock Level.

Fig. 2: For using the Prediction of the Slow-Moving Indicator you have to activate two Predictive Scenarios, one for the Consumption and another for the Stock Level.

Fig. 3: New SAP Fiori detailed page 'Slow or Non-Moving Materials by Plant/Material'

Watch also a short system demo without voice:

The benefits are obvious: Using these capabilities you can lower warehousing costs and increase supply chain efficiency, avoid or reduce scrap materials, and last but not least classify materials for instance suitable for cycle counting in physical inventory.

1.2. Cycle Counting in Physical Inventory

Cycle counting is a method of physical inventory where inventory is counted at regular intervals within a fiscal year. These intervals, or cycles, depend on the cycle counting indicator set for the relevant material. You can use the cycle counting approach, for example, to ensure that stocks of fast-moving items are checked more frequently than slow-moving items.

As a first step to provide cycle counting for Cloud customers, it is now possible to maintain the cycle counting (CC) settings via a self-service configuration user interface (SSCUI). This new SSCUI allows you to customize the Cycle Counting Indicator (A,B,C,D, …) for a plant with the maintained No.of phys. Inventories within the fiscal year. The number of physical inventory intervals will be calculated automatically. The maintained Float time determines the tolerance days until a phys. inventory document will be invalid automatically.

Fig. 4: Self-service configuration UI (SSC UI) for maintaining the cycle counting (CC) settings

The customized CC Phys. Inv. Ind. values are available as foreign keys in the material / product master app for CC classification. As an outlook it is planned for future releases to offer an app for CC mass classification.

What are the benefits of CC right now?

Already the first step of cycle counting capabilities enables you to classify materials for cycle counting, select all materials for a particular Cycle Counting Type and trigger a mass creation of physical inventory documents for the selected materials

Fig. 5: Mass creation of physical inventory documents for a particular Cycle Counting Type

Fig. 6: SAP Fiori app 'Physical Inventory Document Item' displays the Cycle Counting settings

2. Production Planning

2.1. Predictive Material and Resource Planning (pMRP)

Short recap: As described in my past blog post Predictive Material and Resource Planning (pMRP) is our new simulative mid- and long-term planning tool. Thanks to the speed of HANA, it quickly propagates changed demand. The goal of pMRP is to identify potential capacity issues and to evaluate possible solutions as early as possible. The next video explains how to resolve capacity issues with Predictive Material and Resource Planning:

Review also the blog post The Power of SAP S/4HANA #3 – Predictive Material and Resource Planning based on the SAP S/4HANA release 1909.

What's new?

Now, with the 1911 release, production planners can identify additional available capacity for a top level demand, influence planned independent requirements for top level materials during simulation release and shift Top-Level Demand for a Work Center Capacity.

Fig. 7: Shift Top-Level Demand for a Work Center Capacity

Fig. 8: New option to influence planned independent requirements for top level materials during pMRP simulation release. You can select specific version and material level to transfer results as planned independent requirements (PIRs).

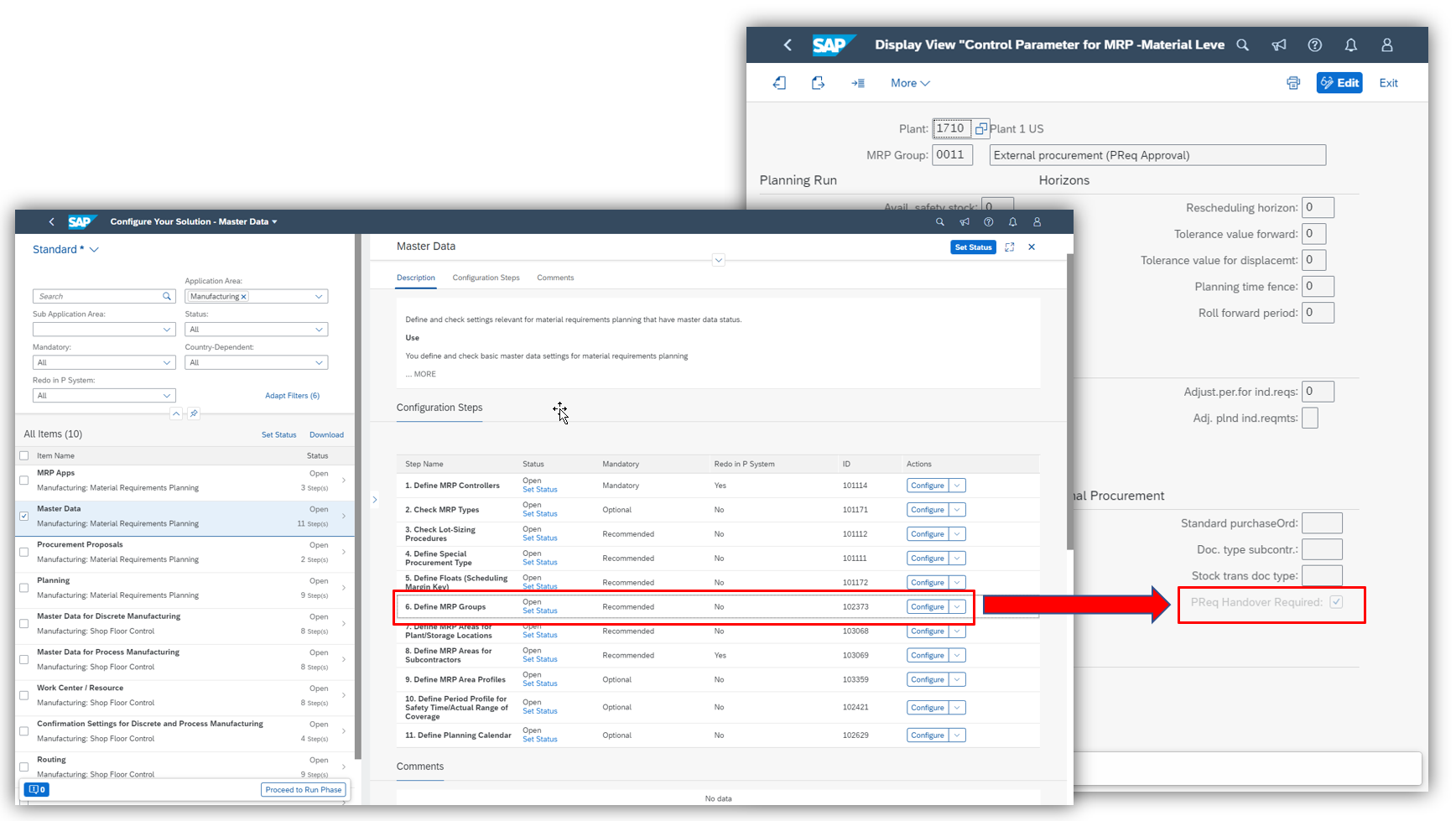

2.2. Material Requirements Planning - Purchase Requisition Handover to Purchasing Required

Materials Requirements Planning (MRP) enables you to ensure the availability of materials. The goal is to ensure that both customer and production demand are available on time and to avoid any disruptions due to missing parts.

The new business configuration setting Purchase Requisition Handover to Purchasing Required determines that the purchase requisitions created automatically during the MRP run need to be handed over to purchasing. Set the Purchase Requisition Handover to Purchasing Required parameter in MRP Group configuration.

Fig. 9: 'Configure Your Solution' app - Define MRP Group

With the extended business configuration you have full control of the handover procedure from production to purchasing, you can block purchase requisitions created automatically during the MRP run by a handover procedure and check purchase requisitions of certain MRP groups before the purchasing department can convert them into purchase orders.

Fig. 10: SAP Fiori app 'Manage Material Coverage' with new Purchase Requisition Handover to Purchasing Required process

Note: The handling of Planned Orders for External Procurement is changed as of SAP S/4HANA Cloud release 2002. When maintaining planned orders, procurement type F for external procurement is not available any longer. Instead you create purchase requisitions for external procurement using the apps of the Purchasing Requisition Processing launchpad group available on the SAP Fiori launchpad.

2.3. Default MRP Areas Assignment & Profile

I want to draw your attention also to a new convenience function which allows you to reduce maintenance efforts for material master data by providing a default assignment of MRP areas:

Reduce data maintenance efforts by assigning a default material requirements planning (MRP) area in ...

Setting the MRP type to 'ND' for materials in specific MRP areas automatically was often asked by our customers. Now this is possible!

3. Integrated Product Development for Discrete Industries

3.1. Order Bill-of-Material (BOM) for Make-to-Order business

The new Manage Order Bill of Material app enables you to create and maintain order-specific bill of material. Typically an order BOM is copied from a material BOM or another order BOM and can be modified for a specific sales order, without changing the material BOM.

Fig. 11: New SAP Fiori app 'Manage Order Bill of Material'

The Make-to-Order Production process described in scope item BJE offers now the option to set up an order BOM that contains the components required for the customer’s specific requirements. A cost estimate can be generated based on order specific BOM.

4. Process Manufacturing

4.1. Third-Party Shop Floor Execution - Process Industry

Process Manufacturing is now ready to go in SAP S/4HANA Clould. The new scope item Third-Party Shop Floor Execution - Process Industry (3W3) covers the setup of the integration from SAP S/4HANA Cloud to Manufacturing Execution systems (MES) for process orders.

A Manufacturing Execution system integrates business and manufacturing processes that help to run efficient, high quality production on the shop floor.

Fig. 12: New scope item 'Third-Party Shop Floor Execution - Process Industry (3W3)'

5. Warehouse Management

5.1. KANBAN process improvements

Scope item Warehouse Kanban Supply into Production (3VT) allows you to replenish material from your warehouse to production in cases where the source storage location is bin-managed, and the production storage location is not bin-managed. With the 1911 release, we are improving the Kanban process for improving your productivity.

5.1.1. Reverse KANBAN Status from FULL to EMPTY in KANBAN Correction

Now, you can reverse the KANBAN Status from FULL to EMPTY in KANBAN Correction. For this purpose we are providing a new warehouse process type for reversals.

Fig. 13: 'Kanban Correction for Control Cycle' app with new Reverse Kanban Status option

5.1.2. Default Exception Code for Setting KANBAN FULL with Difference Quantity

Now, you have the ability to confirm a warehouse task with a different quantity in the SAP Fiori app “Set Kanban Container Status” using the default exception code.

Fig. 14: SAP Fiori app 'Set Kanban Container Status' displays exception code

5.1.3. Material Document and GM Document displayed in KANBAN Information

Now, you can review the material document of the posting change in the Kanban information. With this feature you can faster navigate to related material documents.

Fig. 15: The 'Kanban Information' page displays now the Material Document and GM Document

5.2. Partial Save Enablement for Physical Inventory

For increasing speed and efficiency of physical inventory a new customizing flag provides the so called "proposed quantity" option which proposes a quantity in the SAP Fiori user experience.

Additionally the accuracy of physical inventory will be increased through the user ability to partially save work while taking physical inventory. For this purpose a new counting status "partially counted" is introduced and the SAP Fiori app is enhanced so that users are enabled to partially save their physical inventory work on the document-item level.

Fig. 16: Partially count physical inventory items for a warehouse order

5.3. Replenishment in Warehousing

The new scope item Replenishment in Warehousing (4A2) enables you to plan and automate the creation of replenishment warehouse tasks to ensure the right inventory levels for your products in the areas where picking is done. This scope item supports planned replenishment of fixed storage bins. The replenishment planning can be started either interactively or as a regular application background job. The system creates replenishment warehouse tasks as a result of a planned replenishment run if the current stock is below the defined threshold for the product’s fixed bin. The replenishment quantity is calculated as the difference between the maximum and the current bin quantity. At the end of the process, the warehouse operative confirms the warehouse tasks and makes sure that the stock is moved from the reserve to picking area.

Fig. 17: New scope item 'Replenishment in Warehousing (4A2)'

6. Transportation Management

6.1. Carrier settlement processing

With the 1911 release, carrier settlement is available within SAP S/4HANA Cloud. This allows you to reduce manual efforts in carrier settlement processing by using the financial integration of transportation costs. This enables you for

- accruals postings of transportation costs carried out through service purchase orders (POs)

- invoice verifications based on the received carrier invoices and

- taking the service PO into account for matching

Fig. 18: Scope item 'Order-based Transportation Consolidation (3EP)' enhanced with carrier settlement processing

6.2. Freight Orders with Calculation Errors

The new SAP Fiori app “Freight Orders with Calculation Errors” improves the monitoring and calculations of freight orders. With this app you can

- find the most-critical freight orders with calculation errors based on the planned execution date

- utilize a graphical representation like bar chart for easier prioritization

- search, filter, sort, and group the list of freight orders with calculation errors by relevant attributes

- perform charge calculations on the freight orders with calculation errors

- recalculate the freight orders with calculation errors

Using this app, you get a better transparency of the freight orders requiring action.

Fig. 19: New SAP Fiori app 'Freight Orders with Calculation Errors'

For more information on SAP S/4HANA Cloud, check out the following links:

- SAP S/4HANA Cloud release info: http://www.sap.com/s4-cloudrelease

- Sven Denecken’s SAP S/4HANA Cloud 1911 Release Blog

- The Link Collection for Manufacturing & Supply Chain here

- Early Release Webinar Series here

- Best practices for SAP S/4HANA Cloud here

- SAP S/4HANA Cloud User Community: register here

- Feature Scope Description here

- What’s New here

- Help Portal Product Page here

- Implementation Portal here

Follow us via @SAP and #S4HANA, or myself via @GerhardWelker and LinkedIn.

- SAP Managed Tags:

- SAP S/4HANA,

- SAP S/4HANA Cloud Public Edition

- bill of material

- freight order

- inventory management

- kanban

- manufacturing

- manufacturing execution system

- materials requirement planning

- mrp

- order bom

- physical inventory

- pmrp

- Predictive Material and Resource Planning

- process manufacturing

- Production Planning

- shop floor

- supply Chain

- Transportation management

- warehouse management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

41 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

37 -

Expert Insights

114 -

Expert Insights

224 -

General

2 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

413 -

Life at SAP

3 -

Product Updates

4,672 -

Product Updates

309 -

Roadmap and Strategy

1 -

Technology Updates

1,495 -

Technology Updates

122

- SAP ERP Functionality for EDI Processing: Sales area and Sales Order type for Inbound Orders in Enterprise Resource Planning Blogs by Members

- SAP S/4HANA Cloud Public Edition - Finance-Cost Accounting - Frequently Asked Questions in Enterprise Resource Planning Blogs by SAP

- Save the Date for Our Exclusive SAP S/4HANA Cloud Public Edition 2408 Early Release Series! in Enterprise Resource Planning Blogs by SAP

- Embedded Intelligent Scenarios in SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

- Preferred Success Round Table Discussion with SAP Customers on 29th April @ SAP NOW India. in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 12 | |

| 8 | |

| 8 | |

| 6 | |

| 6 | |

| 6 | |

| 6 | |

| 5 | |

| 5 | |

| 4 |