- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Q&A

- SVT Production scenario

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

SVT Production scenario

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

2 weeks ago

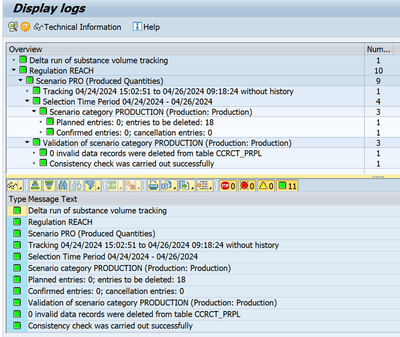

While testing SVT PROD Scenario in development system, we see that the components that are assigned to the product real sub are not considered for tracking. That means no component is being tracked. See the log below

It should be noted here that the component setting is perfectly fine and they are available in CCRCT_EHS _COMP and CCRCT_EHS _REG table with all the relevant information after executing RREGCH_FILL program.

When I execute the RREGCH_VT program, I get the following log, which says some entries are deleted. However, no entry is updated in CCRCT_PRPL table. We use Production order and not the process order.

In one of the cases, out of 5 components, only one component was updated in tracking table whereas in current scenario, out of 9 component, none is being tracked.

I am not able to find out the reason why components are not being tracked when all the prerequisites are fulfilled and what is the connection of 'planned entries deleted' message log with the tracking. How does the Prod scenario works in a simple case where 'X' product has ABC & D components and none are tracked.

Request your comments if it is a known reason.

Thanks

Ashish

- SAP Managed Tags:

- SAP EHS Safety Issue,

- SAP Environment, Health, and Safety Management,

- SAP Product Safety

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hello

i am sorry; Since i am using SVT (now i believe since 2007). the "PRO" scenario was always a "nightmare" (from business point of view and IT point of view).

If somebody is raising the hand and ask you; why was Y tracked but not Z.. to get the answer in most of the practical cases you need more than one day.

There are to many pitfalls to list to help you.

Small hint: your "log" is saying that you track without history

These are the check points you can may be use

1.) based on your story: for any "relevant" material to consider: we have entries in CCRCT_EHS_COMP

2.) Do you use the "SVT material class" on material level?

3.) many entries in CCRCC_FILTER can have effect on tracking result

4.) In many discussion with many people: it is important to understand your "SAP Scenario". Which SAP release do you use? which support package etc.

The reason is: under some conditions the "business" can decide: this object should not been tracked (i skip details). BUt this is only possible starting with a specific SAP release.

IMPORTANT: You must read the SVT OSS Consulting note CAREFFULLY. In this Consulting note SAP tries to explain the "algorithm" which is used: is there something to track yes or no etc.

Generally we can differentiate like:

- the production is refering to what chemists are calling a "mixing"

- the production is generating ONE objects

- the production is generating a "main" objects and "byproducts"

For a "mixing" there is no need of "tracking" as there is no new chemistry generated.

What type of example do you have?

As a hint: your log is saying that tracking is done without "history". You should not go on like this. But you can accept the risk as well.

C.B.

PS: regarding SVT we have a "Blog" in place; but this "Blog" can not help you in your specific situation. Sorry

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Thank you, Christoph, for your comments.

I have some clarification to the question asked.

- Do you use the "SVT material class" on material level? YES

- Which SAP release do you use? which support package etc. Release 617 SP 10

- What type of example do you have? All are substances. None is mixture except one Impurity.

But yes, as you said there are many factors that can affect and need to check.

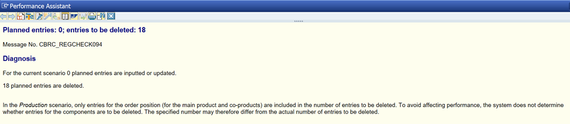

The statement '18 planned entries deleted' is unclear as to what is meant by that. If there are 9 components, then the double is 18 is the only logic I still see :-).

Regards,

Ashish

- SOLUTION DOCUMENTATION - Synchronize Deleted Documents in Product Lifecycle Management Q&A

- How to use Digital Manufacturing MDOs within Custom Plugins – Example: Where Used Report in Product Lifecycle Management Blogs by SAP

- SAP DM Plugin and production process sync call in Product Lifecycle Management Q&A

- Fetch User Details in Product Lifecycle Management Q&A

- IDOC for order confirmation and GR posting in background in Product Lifecycle Management Q&A

| User | Count |

|---|---|

| 4 | |

| 4 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.