In this blog post, I'll like to share some of my observations while exploring material master at SAP DMC after transferring it from S4HANA system.

# Observation 1: Version

Unlike ME, inbuilt version of a material that has been transferred from ERP has become ERP001, ERP002 and so on in stead A, A-1, A-2… This is good as from the version itself it is identifiable whether transfer from ERP. Though while creation a material locally at DMC any version nomenclature can be adopted.

# Observation 2: Description

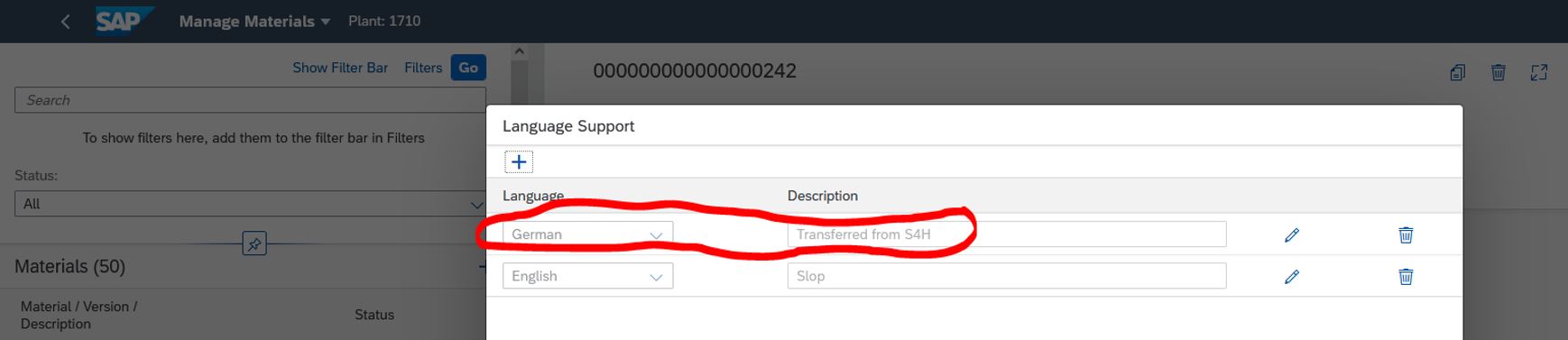

In DMC, material description can be maintained in multiple language. material description can be displayed in multiple languages, based on the language web browser setting.

In case material description is getting maintained in multiple language at ERP then after transferring it is getting taken care at DMC automatically.

ERP:

DMC

# Observation 3: Routing & Recipe option

As DMC is capable to handle both discrete and repetitive manufacturing scenario, at material master both routing and recipe selection option exists in case operation wise component allocation is required.

# Observation 4: Production Type

As DMC is capable to handle both discrete and repetitive manufacturing, at material master “SFC-Based” option to be selected for discrete industry scenario where as “Order-Based” to be selected for process industry.

The

lot size and

quantity restriction fields are updated according to the production type. If an

order-based production type is chosen, then the

Quantity Restriction field will display

Any Number and the

Lot Size field will automatically display the high number

999,999,999.000.

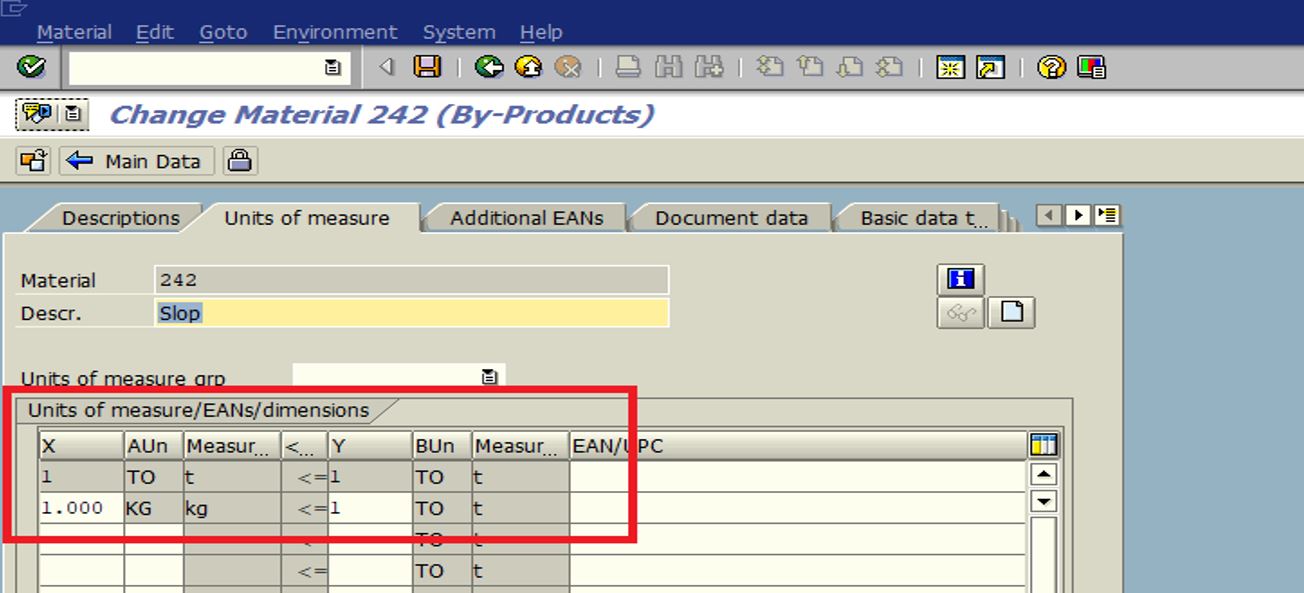

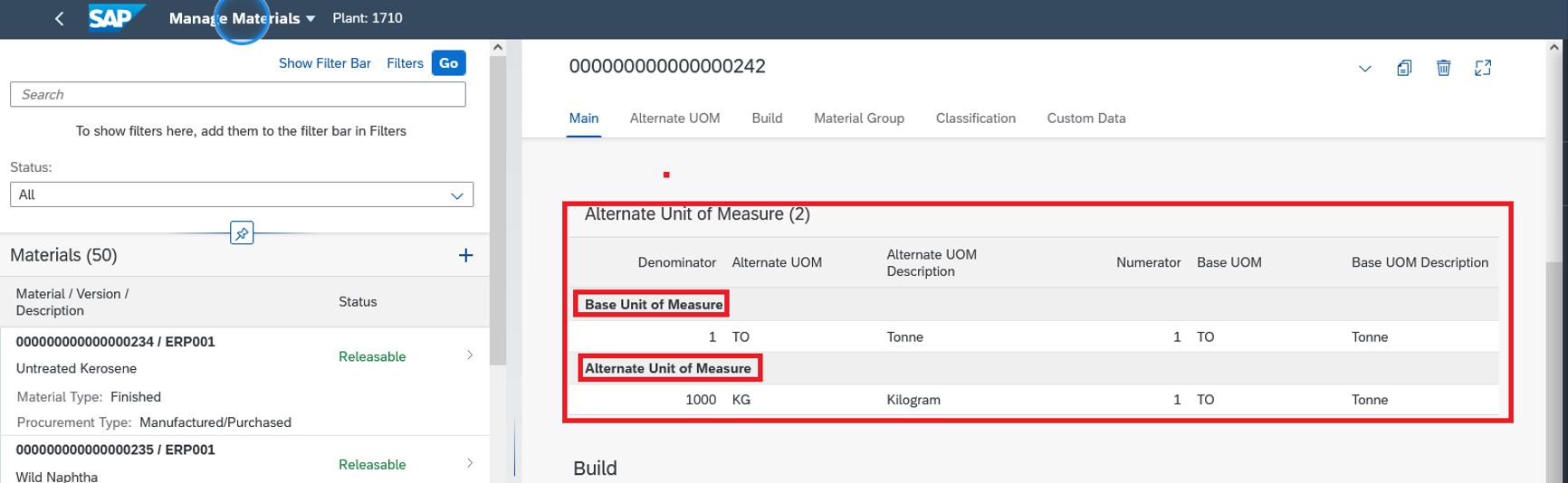

# Observation 4: Alternative UoM Supported

In DMC, alternative UoM is supported. But UoM and alternate UoM can neither be maintained nor be edited locally at DMC. It can only be adopted from the source ERP system.

ERP

DMC

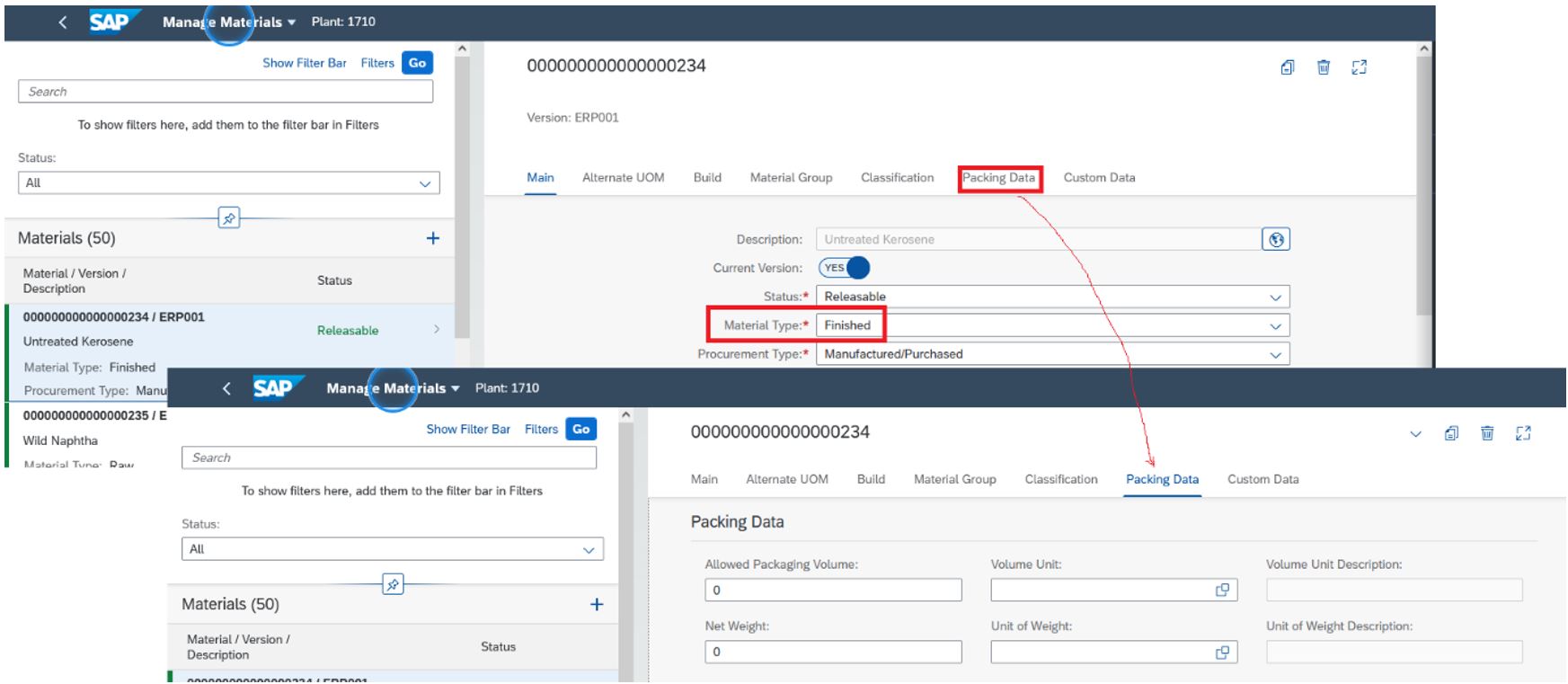

# Observation 5: “Packaging Data” section

“Packaging Data” Section is only visible if material type is selected as “Finished”, “Packaging”, “Returnable Packaging” or “Semi-finished Product”

But packaging information are not transferable from ERP. To be maintained locally at DMC.

Please share, Like and Comment. Share or add points if anything else you want to.

Thanks & Best Regards

Soumya Das

SME - SAP Manufacturing